Anti-static hollow board boxes designed by Yufa Polymer according to the actual needs of the PCB industry have the following functions:

●The ESD corrugated box is permanently anti-static;

●1/3 lighter in weight than injection molded boxes of the same size;

●The size of the ESD corrugated box can be quickly customized according to usage needs;

●The partition area for placing PCB can be customized for design;

●The carrying capacity of the box can be customized for design;

●The box can be added with shockproof and buffer layers;

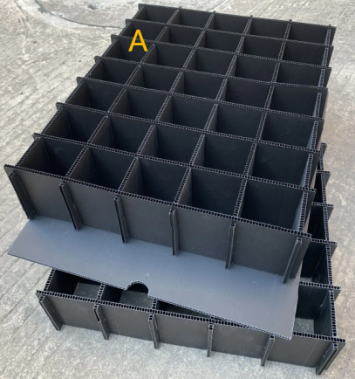

By using the below figures, users can understand the design of ESD corrugated boxes, and these functions can be added or reduced according to actual needs. Our designers will provide the most reasonable design and the most favorable quotation.

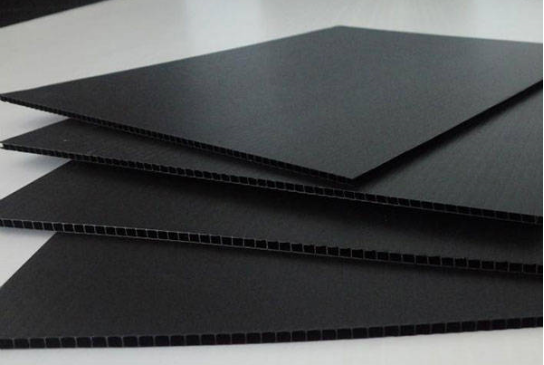

The box material is the anti-static hollow board, with a thickness range of 2mm to 13mm. The box material of the ESD box is generally 4-6 mm, which can be made of single layer or double layer board;

There are various materials available for the internal partition area of the box:

●Anti_static hollow board_ A

●Anti_static EPE foam_ B

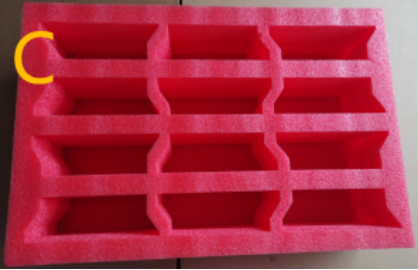

●Anti_static EVA foam_ C

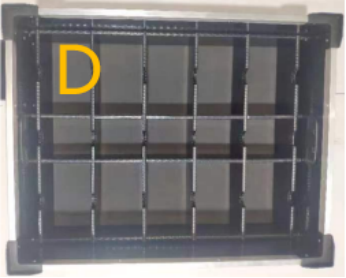

●Anti_static hollow board & anti_static leather_ D

The load-bearing capacity of the ESD corrugated box can be designed in various ways:

●Thickness of anti-static hollow board ①

●The anti-static hollow board has a single or double layer around and at the bottom _ ①

●Add metal reinforcing ribs to the bottom of the anti-static hollow board box or do not add them ②

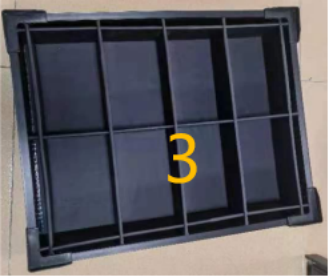

●Reinforcement of the top and bottom edges and corners of the ESD corrugated box, and reinforcement of the four sides of the box ③

Design of ESD corrugated box buffer layer:

●Stick anti-static foam around_ 1

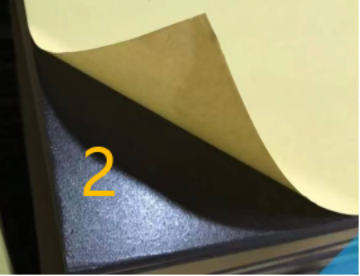

●Stick anti-static foam at the bottom_ 2

●The box and partitions are wrapped in anti-static leather or EVA foam_ 3