In modern industries striving for quality and efficiency, selecting the right material is crucial for success. Our polyethylene (PE) foam material, with its low density, excellent cushioning performance, outstanding water resistance, and exceptional formability, is the ideal choice for thermoforming processes, making your products stand out in the market.

Exceptional Properties of PE Foam Material

1. High-Performance Density

· Density Range: 20 - 100 kg/m³

· Advantage: Our PE foam material is lightweight yet robust, ensuring that the packaging and parts formed through thermoforming do not add extra weight to the product while providing sufficient strength.

2. Superior Tensile and Compressive Strength

· Tensile Strength: 0.15 - 0.35 MPa

· Compressive Strength: 0.02 - 0.10 MPa

· Advantage: The strong tensile and compressive performance of PE foam ensures high durability and reliability during molding and usage, effectively preventing deformation and damage.

3. Excellent Thermal Stability

· Softening Temperature: 80°C - 100°C

· Advantage: Our PE foam material exhibits exceptional thermal stability, preventing decomposition or deformation under the high temperatures of the thermoforming process, ensuring smooth production.

4. Superior Water and Moisture Resistance

· Water Absorption: < 0.05%

· Advantage: The closed-cell structure of PE foam ensures exceptional water and moisture resistance, making it suitable for applications requiring moisture protection.

5. High-Efficiency Thermal and Acoustic Insulation

· Thermal Conductivity: 0.035 - 0.045 W/m·K

· Sound Transmission Class (STC): 15 - 25

· Advantage: Excellent thermal and acoustic insulation properties meet the specific needs of the construction and automotive industries, enhancing product competitiveness in the market.

6. Environmental and Stability Properties

· Characteristics: Non-toxic, low VOC, high batch-to-batch consistency

· Advantage: Compliant with environmental standards, ensuring safe and reliable production processes while maintaining high consistency in each batch, thereby improving production efficiency.

Market Applications: Ideal Solutions for Multiple Fields

1. Electronic Product Packaging

In the high-end electronics market, quality packaging materials are crucial for product protection. Our PE foam material offers excellent shock resistance, moisture protection, and lightweight properties. Using thermoforming technology, the inner lining precisely conforms to the shape of the product, ensuring safety and integrity during transportation.

· Advantages: Shock protection, moisture resistance, lightweight

· Applications: High-end smartphones, tablets, precision electronic components packaging

2. Household Appliances

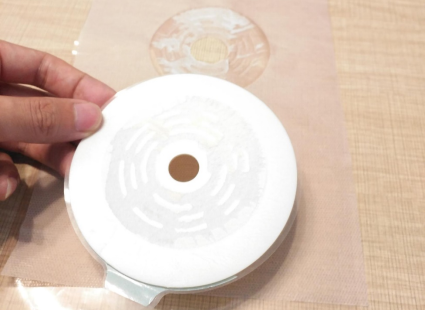

Household appliance packaging demands strict performance criteria for materials. Our PE foam material, processed through thermoforming, provides excellent shock cushioning, moisture protection, and high thermal stability, ensuring that the packaging precisely conforms to the shape of the appliance.

· Advantages: Shock resistance, moisture protection, thermal stability

· Applications: Packaging linings for refrigerators, microwaves, and air conditioners

3. Building Insulation

In the construction industry, energy efficiency and environmental friendliness are core needs. Our PE foam material offers excellent thermal insulation, water resistance, and is lightweight, making it easy to construct and use.

· Advantages: Thermal insulation, water resistance, lightweight

· Applications: Building wall and roof insulation layers

4. Automotive Industry

The automotive industry requires materials that are lightweight and multifunctional. Our PE foam material, utilizing thermoforming technology, is widely used in automotive interiors and shock-absorbing components, ensuring parts precisely conform to automotive designs, enhancing overall vehicle performance.

· Advantages: Lightweight, shock resistance, environmental properties

· Applications: Automotive interiors, seat pads, bumper protection

5. Tropical Fruit Packaging

In the tropical fruit packaging sector, our PE foam material is also an ideal choice. As inner lining protection for tropical fruit packaging, using thermoforming technology ensures the liner conforms perfectly to the shape of the fruit, delivering freshness safely worldwide.

· Advantages: Shock protection, moisture resistance, lightweight

· Applications: Tropical fruit packaging linings

For more information or to inquire about customized solutions, please feel free to contact us.

Contact Us

· Email: info@yufapolymer.com

· Website: www.yufapolymer.com

We look forward to partnering with you to create brilliance together!