"Anti-static container" (ESD container) is a common tool for production turnover, transportation and storage in the anti-static industry, according to the size, weight, handling method, storage time and other elements of the anti-static product carried, choose different "anti-static box".

More and more has been in the "anti-static industry turnover products", to provide customers with professional services, pay attention to the details of customers' product needs, and constantly improve and enhance the design and manufacture of "anti-static box".

The most commonly used anti-static box is "anti-static injected container" (ESD injected container) and "anti-static corrugated container" (ESD corrugated container), customers in the process of use, once the inside and outside of the box to adjust, "anti-static injection box" It is impossible to respond quickly to dimensional changes, so it is bound to extend the waiting time of customers, ranging from 3 months to 6 months or a year as slow.

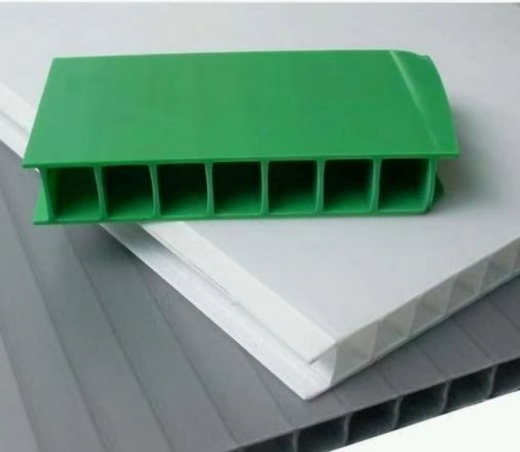

At this time, the "anti-static hollow crate" can indeed meet the customer's requirements for efficiency, according to the size adjustment needs, customized production, but the material of the "anti-static hollow crate" is an anti-static hollow board, the hollow plate plate is composed of many diameters (straight) and upper and lower faces (faces), the middle is hollow (see Picture 1-2), by increasing the thickness of straight and the thickness (the thickness of faces) to increase the carrying capacity to meet the needs of customers.

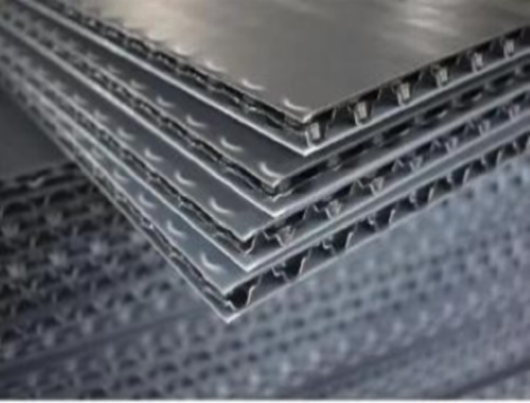

Yufa Polymer has developed an "Anti-static honeycomb cell container" (ESD honeycomb cell container), starting from the mechanical structure of the material (see Picture 3) to solve the load-bearing problem of the box. Compared with hollow plates of the same thickness, the load-bearing can be doubled. As a result, it can quickly respond to the customer's requirements for the size of the "anti-static box", and also increase the load-bearing demand of the box.

Yufa Polymer's newly designed "anti-static honeycomb crate", using 5mm honeycomb panels, through customized processing, made into an "anti-static box" that meets customer needs, although it is not as strong as the "anti-static injection box", but more durable than the "anti-static hollow crate"; Can be customized size, delivery time 7-10 days,The comprehensive cost is between "anti-static injection box" and "anti-static hollow crate".

Picture 1——PP corrugated plate structure,the upper and lower sides of face,in the middle of the straight

Picture 2——Thickens the corrugated plate

Picture 3——PP honeycomb cell plate structure

Picture 4——The sample

Picture 5——Customized Products